Aerial view of Mumbai

Aerial view of Mumbai

From Malawi to Mexico, construction companies are utilizing 3D printing technology to break new ground on housing projects. 3D printing could be our century’s revolutionary printing process, similar to the significance of Gutenberg’s printing press in the 1400s. In 2016 the United Arab Republic, which imports upwards of 70 percent of its labor, became the first country to promote 3D printing in its construction industry, setting a 25 percent target by 2030. Habitat for Humanity built its first 3D house in Virginia last year in half the time – and 15 percent less cost– than a traditional wooden structure. A Texas-based start-up that has already delivered more than two dozen 3D-printed concrete structures in the US and Mexico – half of them to house homeless or extremely poor people – has recently lined up upwards of $200 million from eager investors who believe that such unicorns have the potential to disrupt an industry ripe for change.

This new technology has fired up the imaginations of affordable housing advocates around the world who see producing new and resilient housing quickly and affordably as a “game-changer.” The housing sector is ripe for change with over 1.6 billion people living in substandard housing and another 100 million homeless today. The odds that this latest breakthrough in printing technology could revolutionize the industry and fill the housing deficit will depend on its ability to initiate change and offer net benefits in at least the following three areas:

Beyond brick and mortar and across the housing value chain

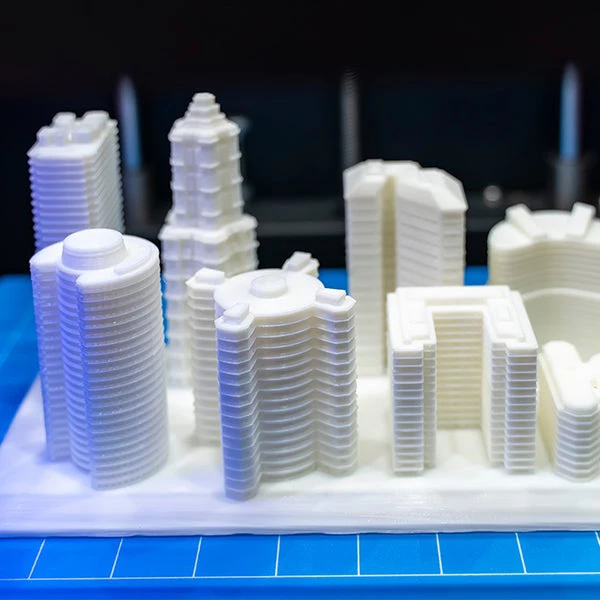

When it comes to affordable housing, every dollar counts. 3D printing promises to dramatically cut construction time and costs (around 15%). However, for 3D printing to truly reach its potential, it will require a lot more investment to enable further cost reductions as well as greater flexibility. Major barriers remain: few housing experts are familiar with the technology and regulators have yet to adapt building codes and permit processes; innovations will also be required across the housing sector’s complex value chain regarding land use, infrastructure, and access to finance. In many urban areas, for example, the cost of land is far more expensive than the cost of construction. 3D construction has focused on single-family housing, therefore going vertical will be critical to solving the global deficit.

Employment

Historically, the introduction of new technologies has caused shifts across job markets, and 3D-printed housing will be no exception. Automation has been canceling low-skilled jobs for decades in rich countries. For emerging economies, where construction jobs are important, 3D printing may be a greater threat – wiping out the jobs of skilled bricklayers around the world. Yet advocates are quick to counter that more than half of those bricklayers could be trained for higher-paying jobs operating and maintaining the 3D printing machinery or developing new software. Innovations have benefits and downsides, but the most successful changes tend to have net positive benefits. There is already encouraging preliminary evidence revealing the shift to 3D printing for housing enables more women to participate in the construction industry.

Climate change

In Malawi, 3D printing reduced construction waste almost tenfold and reduced CO2 emissions by up to 70%. It also reduced transportation emissions when building in remote areas (by as much as two tons per home!), revealing its potential for helping to solve the rural housing deficit. Building technology alone will not stall climate change without smarter urban planning, wider access to transportation, and an increase in housing density. The climate savings of the greenest house on the periphery of a city will be consumed in a household’s costs to commute to jobs in the inner city. 3D printing has proven it can build single-family houses faster and cheaper than traditional methods. The next challenge is to produce high-rise, green multi-family buildings.

The global housing deficit is a massive problem that will require much more innovation than just 3D printing. If you think of the solution to the housing deficit as an iPhone, 3D printing is still only a state-of-the-art screen. Other comparably innovative new parts will also be required, such as: regenerating urban centers, better and greener solutions for transportation, new methods of financing, and different kinds of housing tenure. The full solution will require disruption across the full housing value chain.

It is now up to those of us committed to solving the global housing deficit to come up with the policy ideas that will steer construction companies and investors eager to disrupt the housing industry. Together we could catalyze another printing revolution that will produce safe and affordable housing – while invigorating urban areas, creating new jobs, and protecting the planet.

Related links:

- Subscribe to our Sustainable Cities newsletter

- Follow @WBG_Cities on Twitter

Join the Conversation