Quatre personnes portent un équipement de la tête aux pieds afin de traiter en toute sécurité les installations à forte teneur en PCB.

Quatre personnes portent un équipement de la tête aux pieds afin de traiter en toute sécurité les installations à forte teneur en PCB.

Persistent Organic Pollutants (POPs) are toxic substances composed of organic (carbon-based) compounds and mixtures. They pose adverse effects to the environment and public health and can cause damage to immune, respiratory and reproductive systems. POPs include industrial chemicals such as polychlorinated biphenyls (PCBs) used as heat exchange fluids in electric transformers and capacitors, and as additives in paint, carbonless copy paper, and plastics; and dichlorodiphenyltrichloroethane (DDTs) found in pesticides.

In Lebanon, PCBs are mainly encountered in the electric power sector. Prior to the mid-1990s, they were widely used in power transformers and capacitors in power stations, substations and distribution transformers. Recognizing the importance of the management of POPs, the Government of Lebanon signed the Stockholm Convention on Persistent Organic Pollutants (POPs) in 2002, which aims to phase out and eliminate the production and use of these chemicals.

In 2015, Lebanon sought financial support from the Global Environment Fund (GEF) through the World Bank to implement a project aimed at eliminating PCB contaminated power transformers in an environmentally sound manner. The US$2.5 million 6-year project (May 2015 – March 2021) was executed in close partnership and collaboration with the Lebanese Ministry of Environment, Electricity of Lebanon (Électricité du Liban) and local partners.

The Ministry of Environment ensured proper coordination and execution through a Project Management Unit responsible for supervising all procurement, financial management, environmental and social aspects, and for the monitoring and evaluation of project activities.

Given the risks associated with high content PCB equipment, a country-wide inventory of power equipment was conducted, based on which PCB equipment, oil, soil, and waste were disposed. The project also helped provide capacity building to various stakeholders.

Despite implementation challenges, the project succeeded in surveying 23,044 assets[1] and in identifying carcinogenic POPs. Samples of oil were screened nationally, whereas the confirmatory analysis was done in an accredited international laboratory using gas chromatography. A mobile phone application was also developed to collect information and photos of the transformers being surveyed.

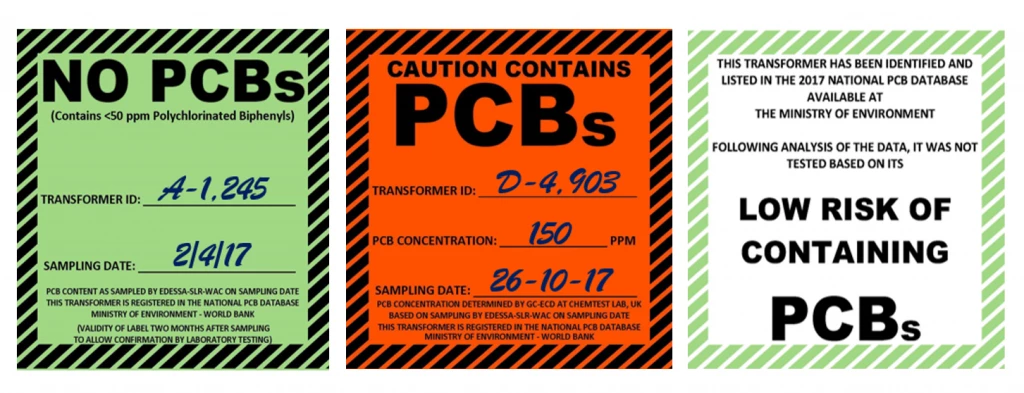

The surveyed transformers, were labelled with one of three types of labels, namely:

- Green Labels (meaning that the transformer turned out to be Clean from PCBs): 10,631 transformers,

- Orange Labels (meaning that the transformer turned out to be PCBs Contaminated): 1,380 transformers, and

- White Labels (meanings that the transformer was not sampled, as it did not meet the minimum criteria[2], thus found to be of Low Risk Containing PCBs): 9,383 transformers.

The inventory created and established a full-fledged database of assets being assessed, recording all collected information, photos, and results. It also paved the way for the development of a national prioritization plan with actions to be done in the short, medium, and long-term, spanning ten years for PCB management to meet the phase-out obligations under the Stockholm Convention.

The GEF-funded project demonstrates that small-value projects can have a big impact, most importantly in generating significant environmental and social benefits. The project was able to dispose of a total of 389 tons of hazardous waste in two batches, one in 2016 and another in 2020. This effort involved an environmentally sound removal, draining, packaging, handling, transport, and disposal process of 282 PCBs from out-of-service transformers, and 606 PCBs from capacitors. The PCB waste was shipped to a licensed facility in France for destruction. The shipment of this type of hazardous waste was fully done in accordance with the Basel Convention, an international environmental treaty controlling the transboundary movement of hazardous waste and their disposal.

It was essential during this project to build national capacities for both public and private sectors, and the project was successful in training more than 500 technicians, administrative officials, academicians, researchers and environmentalists. A draft legal decree that ensures the effective management of PCBs was also developed, aligning regulations with the priorities set by the Stockholm Convention. The project also set the stage for continued engagement and commitment of the Government of Lebanon in addressing wider POPs and waste issues in the country.

While these measures are significant, more work needs to be done to eliminate PCBs including disposing the remaining 1,435 tons of PCB contaminated transformers, maintaining the databases as well as effectively managing any additional types of hazardous waste in the power sector.

Related

[1][1] (22,983) transformers with their three different categories, distribution, transmission, and production, (28) capacitors and (33) drums and tanks.

[2] Criteria of transformers which needed to be tested was based for instance on their date of manufacture, manufacturer, and maintenance history.

Join the Conversation